Philip Steadman

This report was prepared by Philip Steadman at the UCL Energy Institute, as part of a project to advise Islington Council on getting their social housing stock to net zero by 2030. For this reason, there is some focus on London. The paper gives an account of existing carbon reduction and energy efficiency technologies, options to retrofit the existing housing stock, and the anticipated technologies expected to come to market over the next 10 years. It does not make specific recommendations, but discusses the pros and cons of available technologies in general terms.

1. Achieving net zero emissions from dwellings

‘Carbon net zero’ means that the total emissions of carbon added to the atmosphere are no greater than those removed. For the housing stock this will be achieved by the combination of two processes of change, the first in the energy supply system, the second in dwellings themselves. Energy supplies need to be decarbonised, by phasing out the direct burning of coal, oil and natural gas; phasing out electricity production from these fuels; and moving to the generation of electricity from wind, solar, nuclear and other low-carbon sources.

This task of decarbonisation energy supplies is moving fast. Wind power has grown from providing 2% of the UK’s electricity supply to 18% over the last ten years. On Easter Monday 2021 – in unusual circumstances – 60% of electricity used in the country was generated from wind and solar, and a further 16% from nuclear. The process is being propelled not just by climate change policy but by rapid continuing falls in the costs of wind turbines, photovoltaic panels and batteries. Meanwhile the gas supply network to buildings will be either phased out, or possibly converted to carrying hydrogen or other ‘green gases’ whose combustion releases no carbon. On present trends however, there is little prospect of the national UK energy supply system being fully decarbonised by 2030.

The future of national energy supplies will create the context for local decisions, for example by local authorities, and will affect the costs and benefits of different options for housing retrofits. Once a major shift is made towards electricity for delivering heat, alongside a transition to electric cars, there may be national or regional problems with the capacity of the electricity grid.

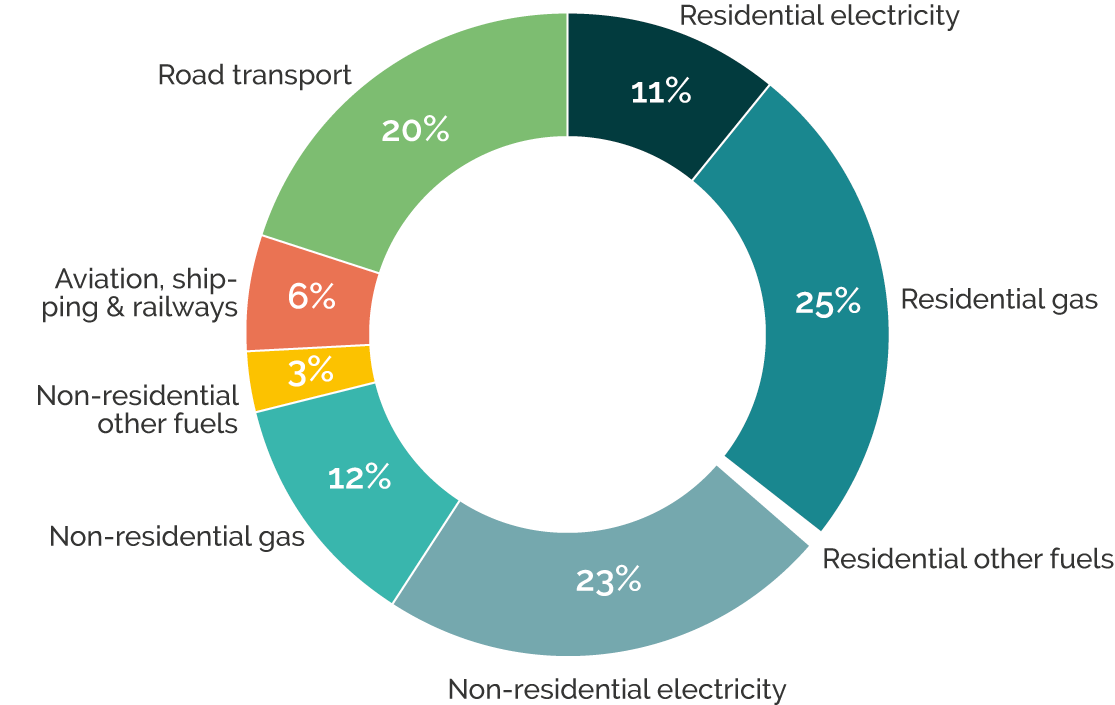

The second part of the route to carbon net zero in houses and flats is to ‘decarbonise heat’, either by converting heating systems to electricity or by moving from natural gas to ‘green gases’. Space heating and water heating are the largest end-uses of energy in housing, and at present these mostly burn gas. Figure 1 shows greenhouse gas emissions in London by sector in 2017 (London Energy and Greenhouse Gas Inventory 2021). Over a third of total emissions (36%) come from the residential sector; and within dwellings, two-thirds of emissions come from natural gas. Then there are lighting, domestic appliances and other equipment using electricity.

The decarbonisation of heat can be complemented and supported by reducing the overall energy demand of houses, in three ways. The first is to upgrade the fabric of dwellings by the insulation of roofs and walls, and by moving from single glazing to double or triple glazing, so reducing heat losses. The second is to use more efficient appliances, and control energy use better. The third is to generate energy from renewable sources locally at the dwelling or estate scale, for which the most promising technology in cities is photovoltaic (PV) installations on roofs. These measures in combination can lower the heat demand, and lower the demand for electricity for lighting and equipment.

Several technologies are available or under development for heating by electricity. Despite the general prevalence of gas heating, a proportion of dwellings have electrical resistance heating at present, some of them using storage radiators. Electrical heating of domestic water in immersion heaters is very widespread. However, these are inefficient ways of using electricity. General opinion in government, industry and the professions favours electrically-driven heat pumps, which can provide heating very much more efficiently than electrical resistance heating. Heat pumps can draw heat from the air, the ground, open bodies of water, or water below ground. They are discussed in more detail below.

Heat can also be supplied collectively to large numbers of dwellings via centralised networks, either within blocks and estates, or on a larger scale, in district heating. The heat is generated in a central plant and distributed to buildings through a network of insulated pipes carrying hot water or steam. The plant can use larger more efficient heat pumps, and can provide greater flexibility and economies of scale over dwelling-level units. Systems can exploit waste heat from a range of sources. Higher densities of housing favour district heating since pipe runs are shorter, heat losses are lower, and more buildings can be connected to one system.

Research with UCL’s 3DStock model has shown that high residential densities in low-rise buildings are associated with lower intensities of energy use for heating, because of the preponderance of flats and terraces, and the decreased areas of exposed external wall (Evans 2018). Other research has indicated that energy intensities are much greater in high-rise blocks than in low and medium-rise (Godoy-Shimizu, 2018). On the other hand, high densities and lack of available land may limit the viability of some renewable energy technologies such as solar, biomass and ground-source heat pumps.

2. Hydrogen as a domestic fuel

One potential change to the wider energy supply system, as mentioned, is the substitution of hydrogen for natural gas, and its delivery through the existing network of pipes below the streets and inside buildings. This would have direct implications for dwellings and their equipment. The subject is currently a topic of lively debate (Baxter 2020; Clark 2020). The gas supply companies and gas distribution companies are pressing hard, with Government support, since this would be a means of maintaining their businesses (All Parties Parliamentary Group on Hydrogen 2021). One attractive economic argument is that the pipe network already exists – although there would be need for some modification, because the pressure at which hydrogen would be supplied needs to be higher. Also, hydrogen reacts chemically with metals, so metal pipework would need to be replaced with plastic. This process of replacement is under way for the mains, but is not complete. Most pipework inside buildings is made from copper or iron.

Some planning studies have been carried out, and pilot schemes are under way. Northern Gas Networks published a report in 2016 on the feasibility of converting gas supplies in the City of Leeds to 100% hydrogen (H21, 2021). The HyDeploy consortium led by the gas company Cadent is planning to deliver a mixture of 20% hydrogen with natural gas (which only cuts emissions by a fifth) (HyDeploy 2021). A private gas network in Keele University has been converted, and HyDeploy is planning larger-scale conversions of public networks in the north-west and north-east of England, the latter supplying 640 homes. Cadent is also working on a feasibility study for a block in Hackney in London. Nottingham University has a ‘Creative Energy Homes’ programme that plans residential hydrogen micro-grids, with facilities for storing the gas locally (University of Nottingham 2021). Both Worcester-Bosch and Baxi, manufacturers of domestic gas boilers, have developed models ready to take hydrogen (Worcester-Bosch 2021, Baxi Heating 2021).

The main arguments against hydrogen as a domestic fuel have to do with the costs and techniques of its production. Gaseous hydrogen is not found in nature, and has to be produced via one of two routes. The first is to convert natural gas chemically to hydrogen. But this process releases carbon, so those emissions would have to be captured and stored. Prototype systems for carbon capture and storage (CCS) exist, but the technology is not presently available at scale in the UK. The second method of producing hydrogen gas is by the electrolysis of water, that is, with the use of electricity. In the nature of the physics, this process is less efficient than the use of electricity supplied directly to buildings for resistance heating; and much less efficient than electrically-driven heat pumps, as we will see. Some experts believe that, for these reasons, the more promising medium-term applications of hydrogen as a fuel are likely to be limited to certain types of heavy transport, and industry.

If schemes to supply hydrogen for domestic use were to be implemented in UK towns and cities, individual house-owners or tenants with gas connections would have little say in the matter. Whole streets and estates would have to be converted at a time, as they were in the 1960s and 70s when town gas was replaced with natural gas. It is possible that a national programme may be implemented, but if so, this is unlikely to happen soon. Analysts see a greater role for hydrogen by the 2040s, when the grid is wholly decarbonised, not for domestic supplies, but in providing long-term energy storage.

3. Reducing heat losses through the fabric of dwellings

The techniques, materials and components used for reducing heat losses from buildings are generally simple, well-established and in wide current use. They include replacement windows, and materials – generally foam plastics, or mineral fibre – for the insulation of cavity walls and lofts. Many houses and flats in England already have these measures installed.

Manufacturers are constantly offering improvements to insulation materials and techniques, and window units, but these tend to be incremental. Some exotic technologies, such as vacuum insulation, are advertised but are unlikely to be cost-effective. Blinds and awnings are more effective in controlling overheating than high-performance glass, although this is worth installing when windows are re-glazed. The main barriers to fabric improvements are not technical; rather they are financial and logistical. The disruption as well as cost of comprehensive fabric retrofits can be significant, especially if occupants have to be decanted. It may therefore be wiser to make comprehensive retrofits in one campaign, rather than shallow retrofits, meaning that properties have to be revisited later. Planning constraints on appearance may limit opportunities for replacement windows and external insulation, especially in conservation areas and listed buildings.

The external insulation of high-rise blocks of flats presents special problems, brought into sharp focus by the Grenfell fire. The majority of plastic wall insulation materials are flammable. Rockwool, made from basalt and recycled furnace slag, is a non-flammable insulator, but being heavy and flexible requires a stronger supporting structure than extruded plastic panels.

In 2018 changes were made to the Building Regulations, governing fire risks and the insulation of residential buildings over 18 metres tall. An advice note issued by the government in 2020 envisages that these regulations may be extended to residential buildings in multiple occupation over 11 metres tall (MHCLG 2020). This would greatly increase the number of properties involved, and could for example apply to houses converted to flats, on 5 or 6 storeys (CBRE 2020).

Solid walls are more difficult and expensive to insulate than walls with cavities, since the insulation has to be placed either inside rooms, which means losing valuable space, or on the exterior, which may alter the building’s appearance. Solid brick walls were general in British houses up until the early twentieth century. A recent analysis of houses with Energy Performance Certificates in London showed solid walls in more than 140,000 houses in the capital built before 1914, and more than 130,000 built between 1918 and 1939 (Liddiard et al, 2021).

Inappropriate insulation measures can lead to the build-up of moisture in solid walls. Excess moisture can result in frost damage, mould growth and wood rot. However, the risks can be minimised by ensuring that moisture absorbed by the wall is allowed to dry out. With internal wall insulation, systems have been developed to promote drying. But the character of the building and its moisture risks needs to be assessed, in order that insulation materials for solid walls are appropriate (Marincioni et al, 2021).

Despite the complication and disruption of internal insulation of dwellings with solid walls, some new products are coming onto the market that are thinner, cheaper, and quicker to install than previous solutions. These also result in less ‘thermal bridging’ (points where heat is directly conducted to the exterior). The financial advantages are however dependent on the area of the external walls, and the airtightness of the dwelling (Leeds Sustainability Institute 2021).

3.1 Passivhaus

Passivhaus is a standard for the performance of buildings, pioneered in Germany, which is designed to achieve very low levels of energy use (Passivhaus Trust 2021). The formal definition of a Passivhaus is “a building in which thermal comfort can be achieved solely by post-heating or post-cooling the fresh air flow required for a good indoor air quality, without the need for additional recirculation of air.” In the UK the standard is generally met through very high levels of insulation, high-performance window design, completely airtight fabric, and a mechanical ventilation system with heat recovery, so that heat is not lost through air changes. By 2018 there were 1000 Passivhaus dwellings in the UK, with a similar number planned. The standard applies to new construction, and is prohibitively expensive to achieve through the modification of existing houses. There is however a separate more relaxed standard, EnerPHit, for retrofit projects.

3.2 Energiesprong

Energiesprong (‘energy leap’) is an approach developed in the Netherlands for achieving very low or zero energy use in housing retrofits or new build (EnergiesprongUK 2021). The organisation works internationally and is represented in the UK. The essential principle is to manufacture, offsite, a complete external insulating skin, complete with windows and doors, with which to encase the existing house or row of houses. This is combined with roof-mounted PV and battery storage. The approach is suitable for simple, repetitive designs of houses or blocks of flats. In Holland 1000 Energiesprong houses a year were being built or retrofitted in 2018, and in that same year the first 10 houses were retrofitted in the UK, in a scheme in Sneinton, Nottinghamshire (Figure 2). Energiesprong UK is now working on 100 council houses in the London Borough of Sutton. The company also offer a ‘build-up’ solution for suitable 3 to 4-storey blocks of flats, in which an extra floor is added to create additional value and offset costs.

3. 4 Ventilation

Older properties can be leaky, resulting in poor energy performance. Unwanted infiltration of air can be reduced through draughtproofing especially around windows, and by plastering. Insulation can also stop draughts. Although air infiltration is undesirable from the energy point of view, there are dangers in low levels of ventilation, including poor indoor air quality and mould growth, leading to health risks such as asthma. In the time of Covid-19, good ventilation becomes even more important. Energy performance and indoor air quality need to be balanced in the context of low-carbon retrofit. Ventilation may be controlled by the occupants or with mechanical ventilation systems. Heat recovery can be combined with mechanical ventilation, as in PassivHaus.

3.5 Controls and meters

Whatever the sources of energy used, efficiencies can generally be improved with the use of proper controls and smart meters. Metering is important for regulating demand and providing flexibility in the use of heat pumps. If tenants and leaseholders are charged fixed fees for heating, not based on actual consumption, then they are not aware of the impact on cost and carbon emissions of high internal temperatures, or of controlling temperatures by opening windows. Smart meters and automated meter reading can make occupants and owners aware of what energy is being consumed, where and when; their use can lead to significant changes in behaviour and management.

3.6 Energy storage

Both heat and electricity can be stored. Energy storage is an important part of decarbonising heat, since this can allow the peaks and troughs of production from renewable sources – due for example to variations in sun and wind – to be matched to the peaks and troughs of demand. Consumers on flexible tariffs can benefit from cheaper rates in off-peak hours by storing energy. Historically, energy has been stored in dwellings as heat in domestic hot water tanks, as well as in storage radiators. Newer thermal storage technologies use latent heat, and are sometimes referred to as ‘heat batteries’. These occupy a half to a third of the space of hot water tanks of equivalent storage capacity (Energy Systems Catapult 2019); but are more expensive.

Advanced electrical batteries for dwellings are now available, in particular the Powerwall produced by Tesla (tesla.com 2021). The cost is similar to a heat battery, but the volume is smaller. Electrical batteries may have shorter working lives than thermal storage systems. The choice of energy storage system for a dwelling is likely to depend on the main source of heat, and whether or not solar photovoltaic panels are installed.

4. Renewable and low-carbon sources of energy

A range of technologies exist for producing electricity or heat with little or no carbon emissions. Many are intrinsically large-scale or confined to favourable or feasible remote locations, and so are of little direct interest to housing in towns and cities. These include nuclear, hydro, tidal, wave and geothermal power. The physics of wind power favours large-diameter turbines, on tall towers. Wind speeds increase with height above ground, and winds are generally stronger over the sea or open land than in cities. A few wind turbines have appeared on the tops of tall buildings in London, but these make little engineering or economic sense, and are mainly for show. Large-scale solar thermal power plants have great promise and are coming into operation, but in desert locations such as north Africa and the southern United States.

4.1 Biomass

Heat can be produced and electricity generated locally by burning biomass – usually wood or waste materials from crop production. Another source is sewage sludge. For heating a boiler, the wood is often supplied as pellets which can be fed to the furnace automatically from a hopper. Raw biomass can also be converted via thermal, chemical or biochemical processes into liquid or gaseous fuels.

The UK government’s domestic Renewable Heat Incentive (RHI) – now phased out – supported the use of wood-fuelled boilers for space and water heating (alongside heat pumps and solar thermal installations) (Ofgem 2021). Evaluation of the scheme showed however that much of the uptake of biomass boilers was by farmers and country estates with their own sources of agricultural waste. One practical problem in urban areas is finding space to store the fuel. There may be better prospects for burning biomass in central power plants, or using biomass to generate hydrogen.

In any case, the combustion of these organic materials releases CO2. There has been much discussion of whether the process can be truly considered as carbon-neutral. When trees grow they absorb CO2: in theory, if wood for fuel is sourced from ‘sustainable’ forests, as much carbon is eventually reabsorbed as is released by burning. Whether this happens in practice is a matter of debate. There can also be problems of local air pollution from burning biomass.

4.2 Solar thermal

Roof-mounted solar panels for producing domestic hot water have been widely used throughout the world for the last hundred years. Designs vary, but most involve arrays of black pipes on black metal supports, beneath glass or transparent plastic covers, through which water or ethylene glycol is circulated. The warmed liquid transfers heat to a domestic hot water tank via a heat exchanger. Units were mass-produced from the 1930s, and found favour in sunny countries including Israel, Japan and the southern United States, until they were largely displaced by cheap natural gas. Owners have described problems with maintenance. In moderate climates, installations may need auxiliary back-up heating for periods of cold weather; although communal systems have been successfully built in Sweden, with inter-seasonal heat stores. There was a vigorous market for solar thermal in Sweden in the early 2000s, but this has faltered more recently, due to competition from heat pumps, and the fall in the price of photovoltaic panels (Sun and Wind Energy 2021).

The demand for hot water in dwellings is reasonably constant throughout the year. Many experiments have been tried with solar space heating, but here the challenge, obviously, is that the times of greatest demand tend to coincide with those periods when sunshine is in shortest supply. For London, solar photovoltaic installations are much more promising.

4.3 Photovoltaic (PV)

Solar PV modules or panels are typically assembled from many cells made from semi-conducting materials that produce electricity from light through the photovoltaic effect. They can be installed on roofs, on the ground, or in large arrays as solar farms. The Mayor of London in his Solar Action Plan (Mayor of London 2018a) has set a target to achieve 1 gigawatt of installed solar energy capacity in the capital by 2030, and 2 gigawatts by 2050. This will be a 20-fold increase on present solar generation in London. 2 gigawatts are sufficient to meet the current electricity demand of some 600,000 typical London houses.

The price and performance of PV systems are continually improving. The international price per watt for conventional solar cells dropped from $76 to $0.3 between 1977 and 2015. (These figures do not include the costs of installation.) PV is now the cheapest method of producing electricity in countries with high solar potential. Efficiencies of PV panels are measured as the fraction of the sunlight falling on the panel that is converted to useable electricity. The efficiencies of panels presently on the market tend to be in the range 14 to 22%. These are likely to improve further. Efficiencies of above 40% have been achieved experimentally.

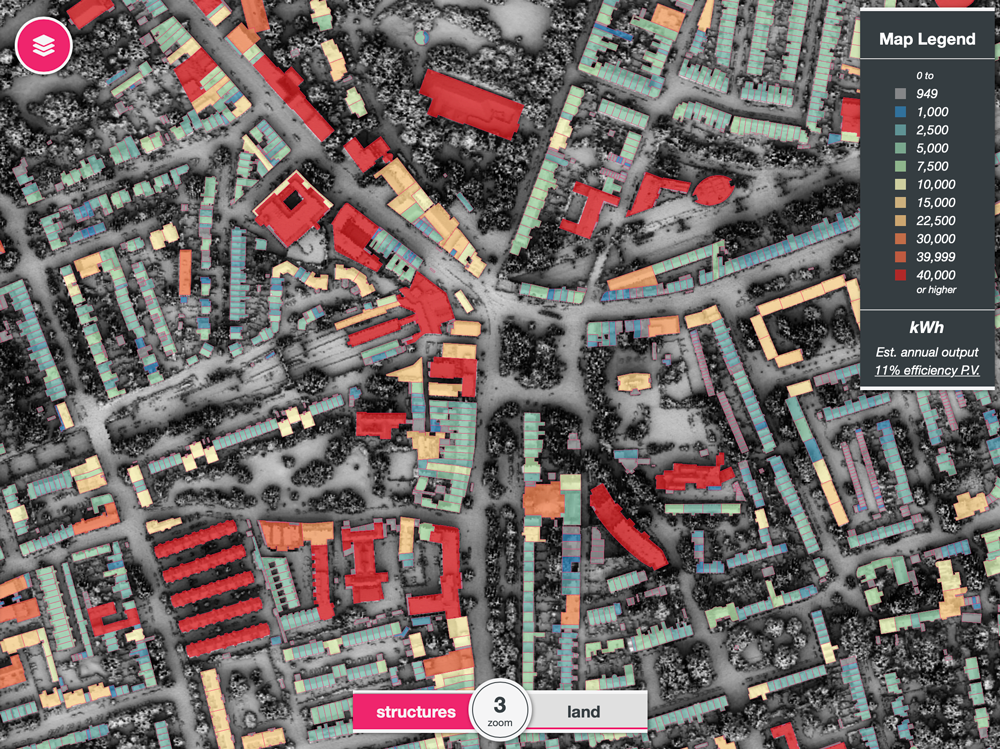

The UCL Energy Institute has developed the London Solar Opportunity Map for the Greater London Authority (LSOM 2021). This is an interactive, publicly available tool that provides estimates of the annual potential of photovoltaic and solar thermal installations on roofs and areas of open land across the metropolis (Figure 3). The figures are derived from calculations of the amounts of solar radiation falling annually on all surfaces, taking account of topography, roof geometry, and any overshadowing by nearby buildings and trees. The orientation and slope of panels should ideally be such as to maximise incident solar radiation throughout the year. This can be precisely calculated for installations on flat roofs or on the ground. Panels on pitched roofs are obliged to take the orientation and slope of the most favourable parts of the roof surface.

UCL have used the Solar Map to calculate the solar photovoltaic potential from all roofs on London’s residential stock. Homeowners can use the map to help them assess the PV potential of their properties, before seeking detailed quotations from installers. Planners may be concerned about the appearance of PV panels, particularly in conservation areas and on listed buildings. One alternative to the standard panel is the photovoltaic roof tile, which is coming on to the market and, since it resembles a conventional tile in appearance, is visually less obtrusive (SolarGuide 2021).

If the electricity produced locally from PV is in excess of the requirements of the buildings, instead of selling this back to the grid, it may be used for the local recharging of batteries in electric cars. Alternatively, it can be used to top up hot water in a cylinder that uses an electric immersion heater.

Small separate PV arrays on houses will of course reduce the occupants’ electricity demand from the mains, and contribute to general decarbonisation. But there will be economies of scale in larger installations, and from a national or local authority perspective, it may be more effective and less expensive overall to encourage PV on the roofs of schools, public buildings, factories and warehouses, as well as for example on canopies over surface car parks, or on railway embankments.

5. Heat pumps

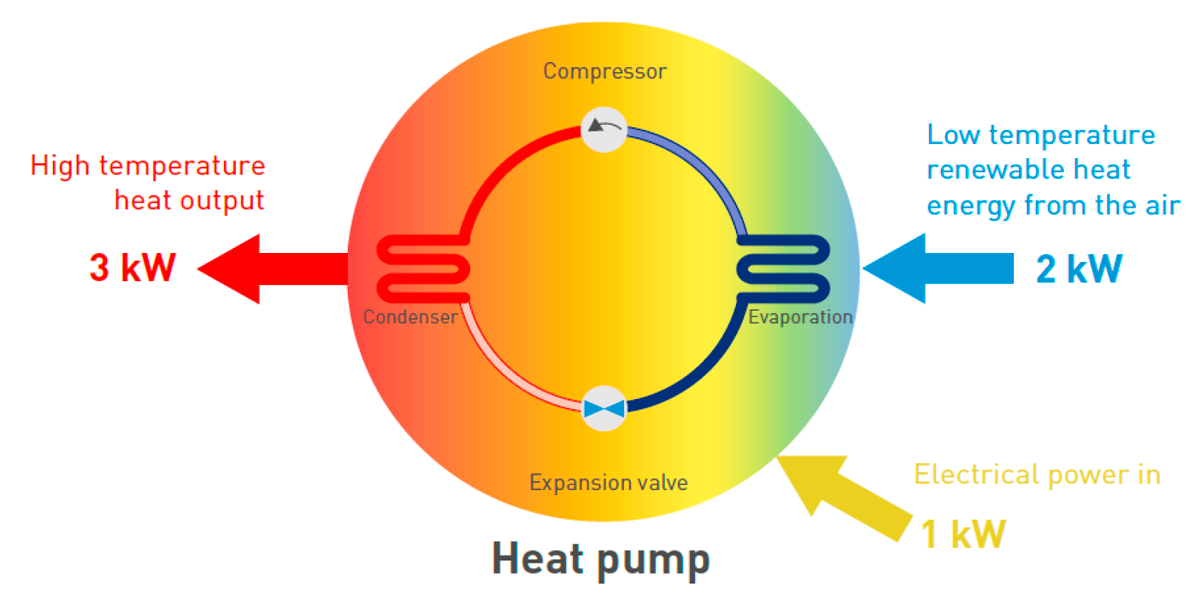

A heat pump is a device that can move heat from a cooler location to a warmer location, in the opposite direction from which it would flow naturally. Heat pumps for buildings take heat either from the ground, the outside air, or a nearby body of water, and use it to provide space heating and water heating. Figure 4 shows the basic arrangement and components for an air-source heat pump. A refrigerant is moved around a circuit of pipework by the compressor (the pump). The refrigerant changes from a liquid to a gas and back again, as its temperature and pressure are altered, and it absorbs and rejects heat. The evaporator draws heat from the air. The condenser transfers the heat to the building’s heating system. Small units can be installed at the dwelling scale, and bigger units in heat networks supplying blocks, estates or districts. There are several advantages to large-scale applications.

Some heat pumps can move the heat in two directions, to provide both space heating and cooling at different times of the year. A domestic refrigerator contains a heat pump that cools the contents by removing heat from the cabinet and releasing it to the room. The first large building ever to be heated and cooled with heat pumps – in this case moving the heat to and from the Thames – was the Royal Festival Hall in 1951. (The system was a success, but was oversized, and was later removed.)

At present, very few dwellings in the UK have mechanical space cooling or air conditioning. However, over-heating is likely to be an issue of growing importance in coming years, as peak summer temperatures rise with global warming. Occupants of south and west-facing flats without cross-ventilation are particularly vulnerable. The 2003 European heatwave caused 14,000 deaths in France, mostly in the north of the country, and among the elderly. France has since initiated a programme of installing air conditioning in care homes.

The heat supplied to a building by a heat pump is essentially ‘free’, and the only energy input is the fuel used to drive the pump. This means that the energy content of the heat supplied can be several times greater than the energy input to the pump. This is illustrated in the example of Figure 4, which shows 3 kilowatts of heat supplied with the input of 1 kilowatt of electricity. The ratio of these quantities is the ‘coefficient of performance’ (COP), which can typically be in the range 3 to 4. If the pump is driven electrically – and provided the electricity is generated from zero-carbon sources – no carbon is emitted.

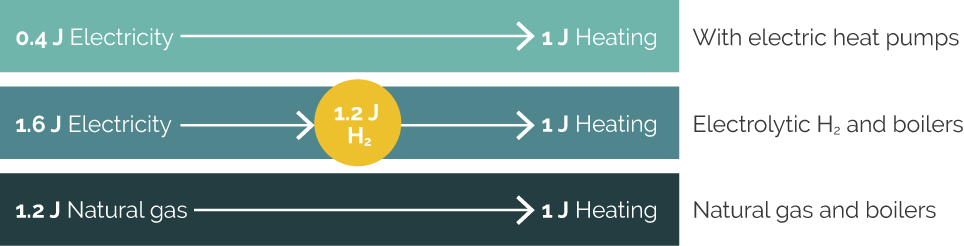

Figure 5 compares the efficiencies of heating with natural gas; with hydrogen produced by electrolysis and burned in boilers; and with electric heat pumps. These are expressed in each case as the typical energy input in joules required to deliver one joule of heat. The numbers show that the heat pumps are three times more efficient than natural gas, and four times more efficient than the hydrogen route.

5.1 Types of heat pump

Air-source heat pumps have two heat exchangers, one outside the building, the other inside. The indoor unit can heat the indoor air directly, or can be used to heat water that is then circulated through radiators. The pumps can heat domestic hot water, and can be reversed to provide cooling. They are the simplest and most popular type of heat pump.

Ground-source (or geothermal) heat pumps need pipes sunk in the ground, either in deep vertical boreholes, or in snaking arrays arranged horizontally in trenches. For single houses there may be difficulties finding enough garden area for the pipes. Opportunities may be greater in housing estates which have significant areas of open land. UCL have developed a digital tool for evaluating larger sites, which positions boreholes and estimates the areas of land required, for a given heat demand.

Ealing Council have replaced underfloor electric heating in eight blocks of 50 flats with individual heat pumps, fed off a shared ground source, with large savings in energy costs (Carbon Trust 2020 p.11). This scheme uses very compact ‘shoebox’ units in the flats, manufactured by Kensa (Kensa Heat Pumps 2021). Hybrid ground and air source heat pumps, drawing heat from either source, can switch from one mode to the other, depending on the outdoor temperature.

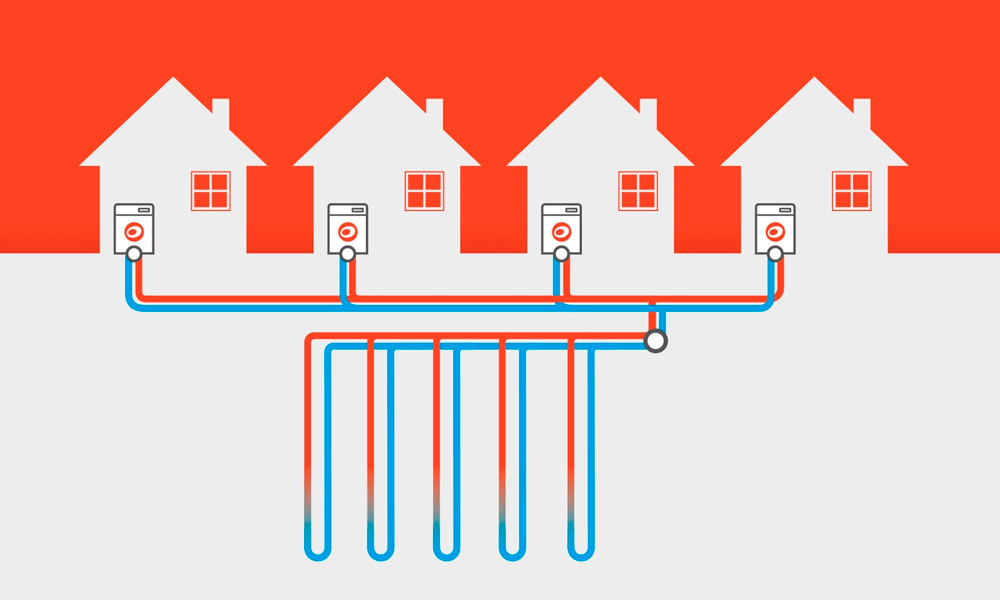

It is possible for a row of adjacent buildings, each with its own heat pump, to be connected to a single ‘ground loop’ or ‘ambient loop’, in a small-scale version of district heating (Figure 6). This can have the advantages of lower drilling costs and reduced heat losses, while providing the flexibility of a shared heat supply.

Water-source heat pumps are limited to locations close to sizeable bodies of moving water. Another option, where the geology is suitable, is to take heat from underground aquifers. The Borough of Southwark has a scheme under way to heat three of its estates, comprising 2175 dwellings, by this means. The work has been contracted to Vital Energi (Vital Energi Southwark 2021). One advantage of this type of heat source is that only two boreholes are needed, one to extract and the other to discharge the water.

The number of domestic heat pumps in the UK is presently very low, accounting for just 1.6% of central heating systems. Around 30,000 units are being installed annually. The Renewable Heat Initiative subsidised an average of just 60 heat pumps in London a year since 2014. They are much more common in Europe: some UK manufacturers including Bosch make heat pumps for the European market. Heat pumps have been used only rarely in the UK for district heating, although there have been applications in Sweden since the 1980s. The UK government has set a target of installing 600,000 heat pumps a year by 2028 in its ‘Ten Point Plan for a green industrial revolution’ (gov.uk 2020).

5.2 Pros and cons of heat pumps

Set against the extreme advantage in the efficient use of electricity by heat pumps, there are some potential drawbacks. The capital costs are generally higher, and installation more complex, than for equivalent gas-fired ‘combi’ boilers providing heating and hot water. The temperature at which water for space heating is circulated by heat pumps is lower than with gas boilers, which may require radiators to be replaced in some dwellings. Cylinders are needed to store the hot water: old cylinders have been removed from many dwellings, and the space used for other purposes.

Heat pumps in general, and air-source heat pumps in particular, can be noisy. Since the latter have heat exchangers both indoors and on outside walls, the noise can affect both occupants and neighbours. Legal limits are placed on noise nuisance by planning law. However, some manufacturers are offering new designs claimed to produce very little sound. These include Ochsner, whose air-source units ‘run quietly’ and have a special ‘silent mode’; and Kensa, whose ground-source pumps are ‘the world’s quietest’ (Ochsner Heat Pumps 2021, Kensa Heat Pumps 2021). The Carbon Trust in a recent report to the GLA say that “Modern air source heat pumps are capable of noise levels well below those required for Permitted Development in dwellings.” (Carbon Trust 2020 p.11). There can on the other hand apparently be special noise issues if multiple air-source heat pumps are installed on one building, and their frequencies resonate. The nuisance can be worse at night when general levels of background noise are low.

The advantages of district heating systems over dwelling-level heating have already been mentioned, and include economies of scale and greater flexibility. It is easier to change the heat source or fuel supplying a centralised plant, or replace the plant itself, than to replace individual heating systems in large numbers of dwellings. Big heat pumps can exploit a range of sources of waste heat including rejected heat from the cooling systems of buildings such as data centres, and from water, waste and sewage treatment plants, and underground railways. Scenarios in the GLA’s 1.5C Compatible Climate Action Plan envisage 100,000 homes or more on district heating in London by 2025 (Mayor of London 2018b).

5.3 Fabric improvements as a prerequisite for heat pumps

Some recent reports on heat pumps, notably that by the Carbon Trust, have stated that improved energy efficiency in dwellings, through fabric retrofit, is a prerequisite for effective heat pump installations (Carbon Trust 2020). This, if true, clearly increases the total cost and complication of getting the housing stock to net zero by this route. Others however have recently questioned this assumption, including experts from Cambridge Architectural Research who advise BEIS on energy use in the housing stock; and Lowe and Oreszczyn at UCL in a briefing for the Centre for Research in Energy Demand Solutions (Lowe and Oreszczyn 2021). If the overriding goal is net zero emissions at lowest cost – not energy efficiency as such – then this could be reached, they argue, with electric heat pumps and low-carbon district heating alone. Universal fabric retrofits would not be needed. “High levels of insulation are not essential to the deployment of heat pumps and are only likely to be cost-effective in easy-to-treat properties.”

A recent report by the Climate Change Committee, Housing – Fit for the Future, estimated that the average cost of fitting a heat pump in a UK home would be around £26,000, giving a total national cost of £650 billion (CCC 2019). Lowe and Oreszczyn believe this figure is an overestimate by a factor or two or three, because the Committee assume that all dwellings would have to be insulated to Passivhaus standards. It is possible, they argue, to compensate for the lower water temperatures at which heat pumps operate, by heating for longer. If radiators prove to be undersized, these can be replaced at an average cost of around £300 each. Very poorly insulated dwellings can be upgraded where necessary. Climate change in any case is reducing the length of the heating season.

References

- All Parties Parliamentary Group on Hydrogen.

- Baxi Heating, The future of heat.

- Baxter, T. 2020. Hydrogen isn’t the key to Britain’s green recovery – here’s why. The Conversation.

- Clark, S. 2020. Is hydrogen the solution to net-zero home heating? The Guardian.

- Carbon Trust, 2020. Heat pump retrofit in London.

- CBRE, Understanding façades and fire risks.

- Committee on Climate Change (CCC), 2019. UK housing: fit for the future?

- EnergiesprongUK, Desirable, warm, affordable homes for life.

- EnergiesprongUK Nottingham.

- Energy Systems Catapult, Pathways to low carbon heating: Dynamic modelling of five UK homes.

- Evans, S., Steadman, P., Godoy-Shimizu, D. and Liddiard, R. 2018. Building stock modelling and the relationship between density and energy use. BSO 2018 Building Simulation and Optimisation, Cambridge, September

- Godoy-Shimizu, D., Steadman, P., Hamilton, I., Donn, M., Evans, S., Moreno, G. and Shayesteh, H. 2018. Energy use and height in office buildings. Building Research and Information, 46: 845–863.

- GOV.UK, 2020. Press release. PM outlines his Ten Point Plan for a Green Industrial Revolution.

- H21, Pioneering a UK hydrogen network.

- H21, Leeds City Gate.

- HyDeploy, Hydrogen is vital to tackling climate.

- Kensa Heat Pumps, Award-winning ground source heat pumps.

- Leeds Sustainability Unit, Thin internal wall insulation: Summary Report.

- Rob Liddiard, Daniel Godoy-Shimizu, Paul Ruyssevelt, Philip Steadman, Steve Evans, Dominic Humphrey, Rayan Azhari (2021). Energy use intensities in London houses. Buildings and Cities, 2: 336–353. doi: 10.5334/bc.79

- London Energy and Greenhouse Gas Inventory (LEGGI).

- London Solar Opportunity Map (LSOM).

- Lowe, R. and Oreszczyn, T. 2021. Building decarbonisation transition pathways: initial reflections. CREDS Policy brief 013, Centre for Research into Energy Demand Solutions, Oxford.

- Marincioni, V. et al. 2021.How can scientific literature support decision-making in the renovation of historic buildings? An evidence-based approach for improving the performance of walls. Sustainability, 13: 1–20. doi: 10.3390/su13042266

- Mayor of London, 2018a. Solar Action Plan for London, Greater London Authority

- Mayor of London, 2018b. Zero Carbon London: A 1.5ºC compatible plan

- Ministry of Housing, Communities and Local Government (MHCLG), 2020. Building safety advice for building owners, including fire doors, Consolidated Advice Note.

- Ochsner Heat Pumps, High tech heat pumps.

- Ofgem, Domestic Renewable Heat Incentive (RHI).

- Passivhaus Trust, What is Passivhaus?

- SolarGuide, Solar roof tile manufacturers

- Star Renewable Energy, 2017. Water Source Heat Pumps around the Regent’s Canal: Final Report to Islington Council.

- Sun and Wind Energy, Sweden’s solar heat market on hold.

- Tesla, Powerwall.

- University of Nottingham, Creative energy homes.

- Vital Energi, Southwark water source heat pumps.

- Worcester-Bosch, The future of fuel.

Chart data: Residential electricity 11%, Residential gas 25%, Residential other fuels 1%, Non-residential electricity 23%, Non-residential gas 12%, Non-residential other fuels 3%, Aviation, shipping and railways 6%, Road transport 20%.

Publication details

Steadman, P. 2021. Existing and future technologies for retrofitting the UK housing stock. Centre for Research into Energy Demand Solutions. Oxford, UK.

Banner photo credit: Alireza Attari on Unsplash