Nick Eyre

Introduction

In 2001 an academic study Socio-technical networks and the sad case of the condensing boiler (Banks 2001), identified the very low uptake of condensing boilers, despite their apparent cost effectiveness. By 2006, almost every gas boiler installed in the UK was condensing. The market was transformed. This note sets out how that change happened.

Early steps

Condensing boilers were developed in the Netherlands in the late 1970s. The technology is significantly, but not radically, different from other boiler technologies. It includes a larger heat exchanger, which cools the flue gas to below the boiling point of water. The water vapour therefore condenses releasing the latent heat of vaporisation and thereby improving the efficiency. The condensate is mildly acidic and needs to be removed through a plastic condensate drain, slightly increasing the complexity of installation.

Early trials established that the technology could deliver significant savings (Trim, 1989). However, by the end of that century, condensing boilers were still not widely deployed with the exception of in the Netherlands (Banks, 2001). With savings of ~10% compared to standard boilers, the potential savings in the UK were the largest for any individual measure in the residential sector. However, as in many other countries, barriers to energy efficiency were constrained adoption. These were already reasonably well-understood, with a typical taxonomy being:

- imperfect information to energy consumers,

- separation of costs and benefits (e.g. the landlord/tenant barrier),

- imperfect capital markets,

- tariff structures which do not reflect marginal costs,

- non-inclusion in prices of externalities, and

- bounded rationality (i.e. deviations from profit/utility maximisation) (Eyre, 1997).

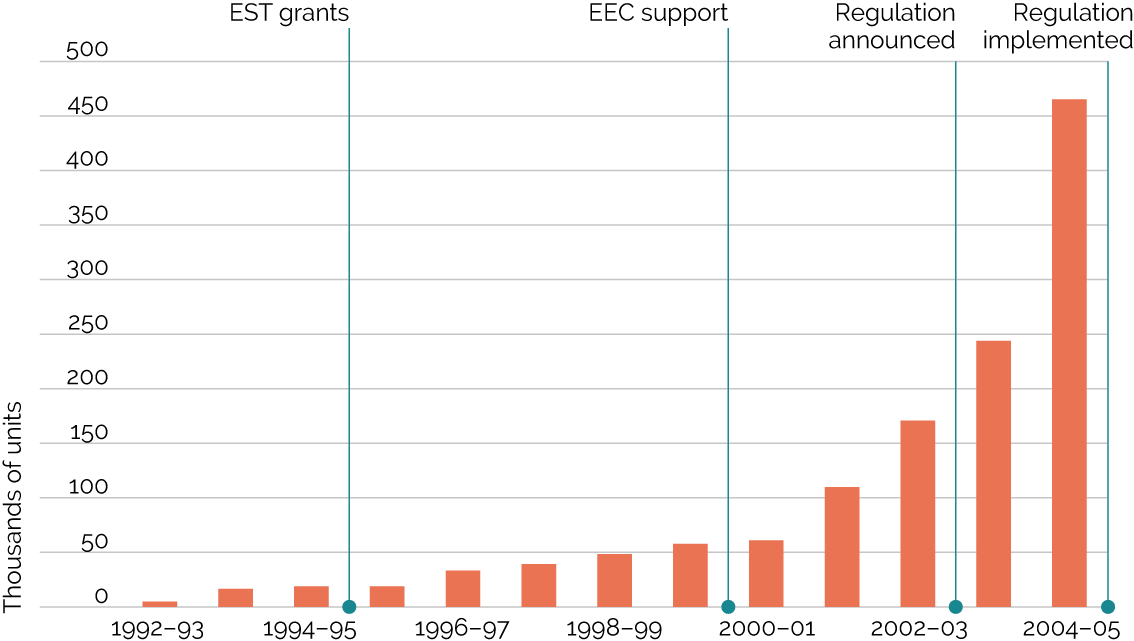

The first step towards policy support was made through an Energy Saving Trust (EST) grant programme which began in 1996. This was funded from the EST’s first annual grant from Defra, established as part of the package to support energy efficiency when the Major government reversed its policy of raising VAT on household from 5% (Mallaburn and Eyre,2014). At the time, the marginal additional cost of a condensing boiler was ~£400 and market share was less than 1%, see Figures 1 and 2. The purchase grant was £200. The market share gradually rose to 3% by 2000, with additional costs falling to about £200.

Image description

Annual installations of condensing boilers grew slowly between 1992 and 2001, with just over 50,000 in 2001. EST grants were introduced in 1995, with support from the EEC in 1999. When the UK regulations were implemented in 2005, over 450,000 installations took place.

In a second significant step, support for gas condensing boilers (technically, boilers with a SEDBUK rating of A or B) was a major part of the initial supplier obligation scheme in gas from 2000. (Supplier obligations were introduced later in gas than electricity due to the opposition of the first gas regulator, Claire Spottiswoode.) They were introduced when gas and electricity regulation were combined, and the duties to set supplier obligations moved to Ministers, under the 2000 Utilities Act (Mallaburn and Eyre, 2014). As with all supplier obligations, different companies operated different levels of subsidy at various times, but cashbacks of £200 falling to £100 were probably typical. By 2003, market share was 10% and incremental costs well below £200.

The big step forward – mandatory condensing boilers

Energy efficiency policy was accelerated in the period 2002-2004. The 2002 Energy Review (PIU, 2002) established the principle of energy efficiency being a core part of the energy policy for the first time. This was confirmed in policy in the 2003 Energy White Paper (HMG, 2003), leading to a detailed 2004 Energy Efficiency Action Plan (Defra, 2004)

Condensing boilers were made mandatory from 1st April 2005. The change was made in the 2003 Energy White Paper, announced on 24th March 2003, thereby giving the supply chain 2 years’ notice. The announcement was not widely predicted externally, even by the heating industry. Bearing in mind that the majority of gas fitters had still never installed a single condensing boiler, it was widely considered to be ambitious, raising fears that poor quality installation would blight the policy.

The regulation was implemented through Buildings Regulations, not EU product regulation. Strictly, the legal liability therefore falls on the owner of the building. In practice, compliance with Building Regulations is delivered by the installer acting on behalf of the final customer. Installers were therefore the critical agents. In many cases, these are sole traders or small companies. In turn, they rely on manufacturers and builders’ merchants, who are larger companies with longer planning timescales and the capacity to understand market changes.

The delivery programme

A rapid programme of skills and training was recognised as critically important in the short period between the White Paper publication and implementation of the new standard. This was begun very rapidly and the extent of the programme is described in the 2004 Energy Efficiency Action Plan (Defra, 2004 p76):

“The Energy Saving Trust, in partnership with the Learning and Skills Council; the ‘Skills for Business Network’ comprising four of the Sector Skills Councils; Defra; the heating industry; the Energy Efficiency Partnership for Homes; CORGI; and City and Guilds, is

launching the ‘Energy Efficiency Installer Certificate’. The aim of this initiative is to provide 70,000 installers with the skills needed to specify and install condensing boilers and properly advise consumers on high-efficiency heating systems. Following the completion of pilot courses in 2003, a series of ‘Train the Trainer’ courses were held in February and March of 2004, and the first of the Installer courses commenced in March 2004. We aim to pass 45,000 installers through the programme by 1 April 2005 and a further 20,000 (bringing the total to 65,000) by the end of 2005. The Training programme will be funded from April 2004 until March 2005 by the Learning and Skills Council, though initial funding to get the programme started will be provided by the Energy Saving Trust (with Defra support). The training covers:

- a brief introduction to climate change and the Energy White Paper

- changes to Building Regulations coming in April 2005.

- the elements of high efficiency system specification (boilers, controls etc)

Those successfully completing the training will receive a Level 3 City & Guilds Certificate – ‘The Certificate in Energy Efficiency from Domestic Heating’.”

The programme of training was completed on schedule and was widely recognised as being successful. Indeed, as Figure 1 above shows, the installation rate increased rapidly following the announcement in 2003, with a 30% market share in the year before the regulation was implemented. Faced with a clear regulation, manufacturers changed their product range and supported the necessary training programme. Installers recognised the need to adapt and undertook the necessary training.

The partners involved in the process represented the broad range of interests needed to be “on board” to make the transition work.

- In the lead, a Government funded agency, in this case the Energy Saving Trust – 100% funded through its Defra grant and with the capability and resources to coordinate the programme, delivered through a specialist ‘Trade Programme’ focused on the supply chain.

- Government itself through the (then) lead Department on energy efficiency, Defra – with a strong commitment to implementing the policy it had advocated in the 2003 White Paper.

- The regulator of gas safety, at that time CORGI.

- The equipment manufacturing industry, in this case the boiler manufacturers – facing the reality of a regulatory constraint and therefore motivated to ensure installers of their products could deliver. In practice, much of the training of existing installers was done by major manufacturers, such as Worcester Bosch and Baxi.

- The funders of trade training, then the Learning and Skills Councils.

- The accreditation agency for skills, then, as now City and Guilds.

- A neutral forum convening discussion between the above partners, the Energy Efficiency Partnership for Homes (EEPfH). At that time, the EEPfH had a secretariat provided by EST, although a separate and independent governance structure. Following the ending of the EST core grant, EEPfH was re-founded as a separate stand-alone company, the Energy Efficiency Partnership for Buildings, but closed in 2015. In the period 2003-2005, the EEPfH had many active working groups, including one on heating, which provided the day-to-day forum for discussions on condensing boiler skills and training.

In practice, the majority of these organisations would not have committed to being partners in the absence of the legal commitment in the Energy White Paper.

Impact and conclusions

The transition to condensing boilers is now well-known to have been extremely successful. Savings per boiler, compared to modelled estimates of continuing to use non-condensing boilers, are approximately 2 MWh/year (Elwell et al, 2015). Over the whole boiler stock this saves ~40 TWh/year of gas and emissions of 8 MtCO2/year.

Public policy support was critical in a number of ways, crucially in setting a regulatory framework that provided clarity to a reluctant industry. The critical policy instrument was the decision in 2003 to make installation mandatory in 2005. This was seen as a brave choice at the time.

The use of regulation was enabled by previous policy instruments of grants and supplier obligations. These developed a growing niche market from the late 1990s, allowing the product to be proven and costs to fall. These earlier stages of the transition could have been done quicker if some policies had not been blocked by the gas regulator.

Partnership was critical to delivering the change within the 2-year period between 2003 and 2005. The transition was delivered through a training programme for the boiler installation supply chain. This was a collaborative effort between publicly funded agencies and the boiler industry.

In summary, a combination of regulation, incentives and skills support was needed. This is what would be expected from innovation theory for a change in the dominant regime in a sector (Geels, 2002). It is consistent with wider analyses of the role of multiple policies in delivering energy efficiency (Rosenow et al, 2016).

Implications for future changes to heating

In comparison to other heating system changes, the switch to condensing boilers is relatively easy. There were some early teething problems with freezing of condensate pipes, and consumer acceptance of “pluming”, but these were quickly overcome. Most people were

unaware they had a condensing boiler, because it was a “like for like” replacement for older technology, with no perceptible change in performance. It did not involve whole new skill sets or supply chains in a way that seems inevitable for zero carbon heat.

Some of the conclusions set out above are therefore important lessons for the zero carbon heating transition. A clear regulatory framework will be needed; support for early movers will be important to establish a viable market as soon as possible; and the supply chain will need to be supported to gain the necessary skills.

However, the greater complexity of future changes means that there will be additional issues. The bigger changes in technology appearance, performance and cost raise much more significant issues for consumer acceptance. The changes implied for installers are more profound and therefore will take longer. Perhaps, most significantly, there are major implications for networks (electricity, gas and/or heat), where change will need to be coordinated with change in end-use technology.

References

Banks, N. 2001. Socio-technical networks and the sad case of the condensing boiler. In: Bertoldi, P., Ricci, A., de Almeida, A. (eds) Energy efficiency in household appliances and lighting. Springer, Berlin, Heidelberg.

Defra, 2004. Energy efficiency: The Government’s Plan for Action. CM 6168. London: Crown Copyright.

Elwell, C.A., Biddulph, P., Lowe, R. and Oreszczyn, T. 2015. Determining the impact of regulatory policy on UK gas use using Bayesian analysis on publicly available data. Energy Policy, 86: 770–783. doi: 10.1016/j.enpol.2015.08.020

EST, 2008. Energy Saving Trust. Personal communication.

Eyre, N. 1997. Barriers to energy efficiency more than just market failure. Energy and Environment, 8(1): 25–43. doi: 10.1177/0958305X9700800103

Geels, F.W. 2002. Technological transitions as evolutionary reconfiguration processes: a multi-level perspective and a case-study. Research Policy, 31(8–9): 1257–1274. doi: 10.1016/S0048-7333(02)00062-8

Department for Trade & Industry, 2003. Our energy future – creating a low carbon economy. Energy White Paper. London: Crown Copyright.

Mallaburn, P. and Eyre, N. 2014. Lessons from energy efficiency policy and programmes in the UK from 1973 to 2013. Energy Efficiency, 7(1): 23–41. doi: 10.1007/s12053-013-9197-7

Performance and Innovation Unit, 2002. The Energy Review, pdf. London: Crown Copyright.

Rosenow, J., Fawcett, T., Eyre, N. & Oikonomou, V. 2016. Energy efficiency and the policy mix. Building Research & Information, 44(5-6): 562–574. doi: 10.1080/09613218.2016.1138803

Trim, M.J.B. 1989. Energy in housing: UK monitored case studies indicate opportunity for energy‐saving investment in domestic condensing boilers for family and sheltered housing. Batiment International, Building Research and Practice, 17(2): 108–113. doi: 10.1080/01823328908726950

Publication details

Eyre, N. 2020. The story of condensing boiler market transformation – a briefing note for BEIS. CREDS Policy brief 025. Oxford, UK: Centre for Research into Energy Demand Solutions.

Banner photo credit: Alireza Attari on Unsplash