The DeViz Project highlights how identification of thermal defects during construction can assist early rectification and professional understanding of thermal performance.

Technologies and materials for building decarbonisation don’t necessarily perform as well as assumed. Many kinds of construction defects – often invisible – undermine performance significantly. Defect Visualisation (DeViz) suggests how industry stakeholders can be positively engaged to take the issue more seriously.

UK buildings are responsible for around 17% of our national emissions, and emissions from heating buildings makes up around 78% of all building’s emissions.

Research and policy debates often assume the perfect deployment of technology (for example, in models and scenarios), but there is often a significant gap between design intent and real-world performance.

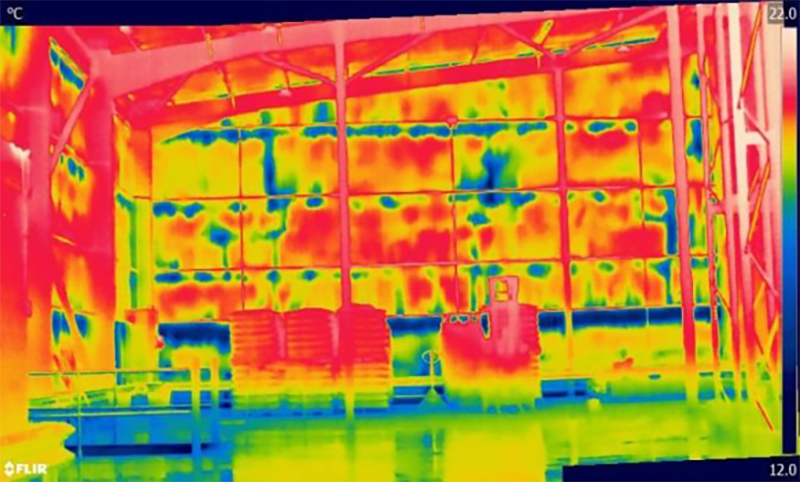

The design-performance gap can be very significant – not just a few percentage points, but 50-100%, or even more. One cause is the presence of widespread, but invisible, thermal defects: discontinuous insulation, gaps in vapour barriers, thermal bridging at junctions between building elements (e.g. around windows and doors), water ingress, and more besides (Figure 1).

Thermal defects in buildings can be difficult for site staff to identify. Often, they are hidden behind finishes such as plaster or happen after installation. However, some thermal defects can be quickly identified using thermal imaging.

The Defect Visualisation (DeViz) project set out to engage site supervisors with these issues at a point part-way through the construction process, so that any defects found could be remedied reasonably quickly and cheaply. Site supervisors were given basic training in the use of thermal imaging cameras and asked to use the technology to assess their own building project.

We assessed their emotional response to the experience with qualitative methods and concepts from psychology. For example, that images ‘afford’ enhanced ways of communicating an understanding of topics such as heat loss, which can 1) be difficult to otherwise fully appreciate, and 2) which connect to behaviour choices.

We also explored how the engagement with an unfamiliar technology might prompt different reactions. Starting a discussion about the cause of thermal defects in buildings can sometimes be a tricky topic with construction professionals. It hints at issues of quality control or workmanship, which could be perceived as mistakes being made and called out.

However, this is not necessarily the case. The DeViz Project wants to take the ‘heat’ out of this conversation, by thinking in terms of a no-blame culture and changing the conversation to one that acknowledges that defect identification should be a ‘normal’ pathway towards better quality. For that idea to work, we needed to know how site supervisors would react to the thermal images they created. Would they dismiss them, find someone to blame, see it as a valuable tool to aid quality assurance or something else entirely?

The on-site research showed that site supervisors responded in an overwhelmingly positive way, seeing the thermal images as a powerful means of improving their own understanding as well as that of contractors working on site, and focusing attention on finding a remedy rather than apportioning blame. Using thermal imaging technology in this way significantly enabled better understanding of previously hidden defects and their possible causes:

- Some thermal defects can be materials related (collapsing or slumping insulation [See the example in Figure 1], decay of vapour layers, or other materials).

- They can be impossible to see (hidden behind layers of building finishes).

- They can be the product of a designer’s or client’s requests.

- They can result from multiple trades impacting on previous workmanship.

- And some can be workmanship related.

Reducing thermal defects requires (and assumes) that site supervisors be skilled and able to know, understand and assess their sub-contractor’s work. Yet, understanding the thermal consequence of a particular piece of work on site, is a different level of seeing and understanding.

The affordances of this approach seem very positive:

- Images, in general, can capture attention in a way that is difficult using other communication mediums. In particular, thermal images can portray very specific actions that need to be taken (e.g. replacing the insulation in Figure 1).

- Thermal images can be used to draw attention to the thermal consequence of an action, which is difficult to understand otherwise. How can one imagine the magnitude of temperature difference caused by a small, missing detailing? A thermal image can contribute to this insight. Site Supervisors can benefit from these or use them to communicate with subcontractors and other stakeholders.

Point 1 and 2 are important from a behavioural and behaviour change perspective. It is often not enough to know ‘about’ defects, when the type of knowledge needed is a more action-related knowledge, In other words, helping individuals to know what to do or how to rectify a situation can improve their understanding. When people can intuitively see and know the benefits of taking that action, their understanding of the effectiveness of their actions is improved. These aspects of understanding can be seen as preconditions that are needed to drive a change in behaviour.

DeViz has trialled an approach that could contribute towards reducing the design-performance gap in buildings. But, importantly, this activity could also improve the understanding of construction workers, such that they take those insights with them to their next project, too.

However, there are challenges to the use of thermal imaging which the DeViz Project is investigating. Firstly, there are methodological issues to obtaining good images by heating (or cooling) the construction site to achieve a 10 degree difference between the internal and external temperatures. Also, some knowledge of thermography is required to interpret (and avoid misinterpreting) the thermal images.

Secondly, images are not neutral. They can trigger negative responses of unease, thereby generating defensive psychological reactions, for example, denial or derogation of the importance of the issue. Images are interpreted through the viewer’s prior experiences, beliefs and perceptions. It is therefore not possible to predict how an image will be accepted. This is where the prevailing environment can help, if it is supportive, makes time for defect identification, makes it an expected and active part of the job role, and with everyone feeling involved in the process, rather than having a blame culture.

Technologies and practices such as thermal imaging offer potential in helping construction professionals to achieve net-zero targets. There may be even more potential when the industry is an open one, taking a positive and transparent approach to accepting the incidence of defects and rectification.

So let’s take the heat out of identifying thermal defects!

- See the DeViz Project research paper

Banner photo credit: DeViz project